For example, if the fuel tank maximum capacity is 10,000 KG, then the tolerance of the gauging is 0.02 (airplane without a densitometer) * 10000 = 200 KG.

Fuel quantity indicating system full#

The total tolerance for the FQIS system is based on a full tank. The fuel flow indication is integrated over time to calculate the fuel used for each engine.ħ37-600/-700/-800/-900 with densitometer: During cruise, the tolerance is less than 1.5%. At engine idle, the system tolerance can be 12%.

The accuracy of the fuel flow transmitter is a function of the fuel flow. The system tolerance is then +/- 300 KG at any fuel level within the tank. For example, if the fuel tank maximum capacity is 10,000 KG, then the tolerance of the gauging is 0.03 (airplane with analog indicators) * 10000 = 300 KG. The 737 fuel quantity indication system has the following accuracy tolerances:įQIS accuracy with digital indicators: +/- 2.5 %įQIS accuracy with analog indicators: +/- 3.0%

NG: The engine spar valves and APU are normally powered by the hot battery bus but have a dedicated battery to ensure that there is always power to shut off the fuel in an emergency.Īnalogue Fuel Gauges -1/200's and some older -300'sĭigital Sunburst Fuel Gauges - Simmonds 4 Tank - 3/4/500'sĭigital Sunburst Fuel Gauges - Smiths - 3/4/500's They were solenoid held and automatically moved back to OFF after one minute. The 1/200's had heater switches these used bleed air to heat the fuel and de-ice the fuel filter. The FILTER BYPASS lights were FILTER ICING on the 1/200. The -1/200 panel also has blue VALVE OPEN lights similar to that on the crossfeed valve. The NG's have separate ENG VALVE CLOSED & SPAR VALVE CLOSED lights in place of FUEL VALVE CLOSED.

Fuel quantity indicating system series#

The fuel panels for the various series have not changed much over the years. The AFM limits are higher, but not normally achievable with standard SG's. The low level sensing system is powered by 28 vdc.The maximum declarable fuel capacity for tech log, nav log, etc is 16,200kgs for 3-Tank Classics, 20,800kgs for NG's and up to 37,712kgs for BBJ's depending upon how many tanks the customer has specified (max 12). The L or R FUEL LOW light capsule is lighted when the relay releases. When the resistance of the thermistor decreases, the relay releases as the bridge approaches a null condition. The output signal which results from the imbalance is amplified to operate a relay. The thermistor is part of a normally unbalanced bridge circuit in the thermistor control unit. Its temperature then rises and its resistance decreases. NO BREAK - WORK HARDER When the fuel quantity falls below the 20 percent level, the thermistor in the low fuel sensor is no longer cooled by fuel.

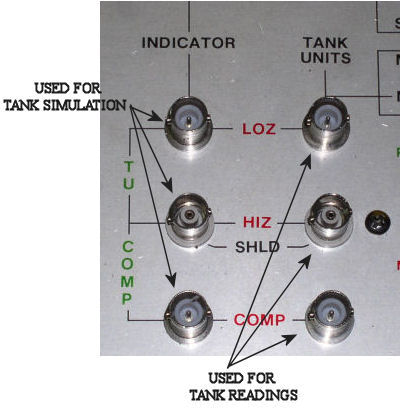

NO BREAK - WORK HARDER The low level sensing system includes a dual thermistor control unit in the console, a low level sensor in each center tank unit at the 20 percent level, and two capsules, L or R FUEL LOW in the master caution panel. The indicator is powered by 115 vac and electrical connection is through a connector at the rear of the indicator. NO BREAK - WORK HARDER The rear of the indicator contains four adjustments for full and empty calibration, two for the dial and two for the digital readout. The variable resistor wiper arm is mechanically linked to a counter mechanism which displays the total fuel quantity in pounds. A printer on the wiper shaft moves across the calibrated scale and indicates the quantity in single-tank quantity indication. The servo motor moves a variable resistor wiper arm thru reduction gears to reestablish the bridge balance. This signal is amplified to drive a servo motor. The unbalance results in a gage correction signal at the bridge output. This causes an unbalance in the fuel quantity indicator bridge circuit. A change in fuel level causes a change in the capacitance of the tank units. NO BREAK - WORK HARDER The indicating system includes the fuel quantity selector switch and indicator clamp mounted on center instrument panel, and ten tank units, one in each forward or aft aux tank and three in each main tank. TM 55-1520-240-23-7 8-57 MISCELLANEOUS INSTRUMENTS (Continued) 8-57 FUEL QUANTITY INDICATING SYSTEM Description This system includes the fuel quantity indicating system and a low level sensing system.

0 kommentar(er)

0 kommentar(er)